INNOVATION from CAPSULAE : Development of microcapsules without microplastic

Plastic pollution is a global scourge. There are plastics visible to the naked eye in oceans or rivers, but there are also microplastics, particles up to 70 times smaller than the thickness of a hair. These microplastics have very diverse origins, and can in certain cases come from the degradation of microparticles intentionally added to formulated products.

The vast majority of microcapsules currently used in the fields of phytosanitary products, cosmetics, and even household detergents fall within the definition of microplastics. Indeed, these microcapsules (essentially melamine-formaldehyde type microcapsules) do not meet the biodegradability criteria.

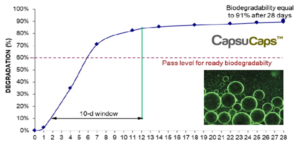

Based on this observation, CAPSULAE initiated research studies several years ago enabling the formation of biodegradable microcapsules from biosourced polymers. This first generation of biodegradable microcapsules, based on a proprietary technology called CapsuCaps™ (EP3397378), is currently used successfully for applications in the field of plant protection and biocontrol. The biodegradability of the CapsuCaps™ microcapsule membranes was measured at more than 90% in 28 days according to the standardized OECD 301B method.

Figure 1: Biodegradability of CapsuCaps™ microcapsules

However, the use of CapsuCaps™ technology in the field of detergence and laundry products does not achieve the desired level of performance. In order to meet the requirements of these specific markets, CAPSULAE has partnered with the Institute of Molecules and Materials of Le Mans (France). The combination of complementary skills has recently led to the emergence of a patented second generation of microcapsules based on click chemistry. The first tests carried out on perfume microcapsules introduced into detergents and laundry detergents show that the new formulations provide a membrane that is both biodegradable and stable over time (several months). A new series of tests is currently underway to confirm the initial results.

CAPSULAE’s ambition for the future is to reduce the environmental impact of microencapsulation processes, thus helping to guarantee a clean, healthy and safe living environment. To do this, CAPSULAE adopts the SAFE BY DESIGN eco-design approach which integrates the safety dimension at the earliest stages of the its innovations development (inherently harmless substances, materials, products and processes). The objective is to propose new chemical encapsulation processes avoiding the generation of microplastics at the end of the life cycle of microcapsules.

Plastic pollution : A worldwide issue

In recent years, much attention has been paid to environmental problems caused by plastic pollution. Plastics are everywhere, from food packaging to beauty care, construction materials and textiles. If not disposed of or recycled properly, they can subsist in the environment for centuries and break down into smaller and smaller particles. These small particles (generally less than 5 mm) are called “microplastics” and are a source of concern because they do not biodegrade, leading to irreversible pollution of ecosystems and the food chain.

Microplastics are solid particles of plastic, composed of mixtures of polymers and functional additives. They can be produced unintentionally as a result of the deterioration of larger pieces of plastic, such as car tires or synthetic textiles. However, they can also be manufactured intentionally and added to products for a specific purpose, for example to serve as exfoliating beads in facial or body scrubs.

In 2017, the European Commission launched an ambitious approach aimed at reducing or avoiding the release into the environment of microplastics intentionally added to formulated products (500,000 T over 20 years) through the taking of drastic measures at the regulatory level. This approach resulted in October 2023 in a first series of prohibitions, and the implementation of a transition period for specific products in order for stakeholders to find and develop alternative solutions.

Capsulae Research and Innovation Center, subsidiary of INNOV’IA

Contact-us

"*" indicates required fields