CAPSULAE offers a full range of services for the development of innovative ingredient formulations: feasibility study and proof of concept, design of innovative solutions and resolution of formulation issues, transfer to pilot scale, industrialization, and micro-production.

Contract Research

Research and Innovation have always been at the heart of our DNA. As part of the first exchanges under confidentiality agreement, an in-depth analysis of the customer’s request is carried out, in order to establish detailed specifications that meet the technical and economic constraints of the project.

A research service is proposed when the resolution of the customer problem requires the development of new formulations, the evaluation of alternative technological pathways, and the need to conduct exploratory work prior to the production of the first laboratory batches.

The service provided consists of 3 successive steps:

- Feasibility study / Proof of concept (evaluation of different technical approaches, testing of several formulations and production of samples at the laboratory scale, analysis and characterization of the samples produced, assessments and recommendations);

- Optimization / Validation of the developed process (adjusting key operating parameters, producing demonstration batches on a pilot scale, studying change of scale);

- Transfer to a semi-industrial or industrial scale (assistance in scaling up to industrial production, internalized or outsourced)

DEVELOPMENT OF MODELS AND PROTOTYPES, MICRO-PRODUCTION, SUPPORT FOR INDUSTRIALIZATION

The development of models and prototypes is proposed when the resolution of the customer problem is possible through the adaptation of an existing solution, already proven, and identified in our large technological portfolio. This service ensures a quick and optimal solution, perfectly meeting the technical specifications of the project, and enabling immediate industrialization.

The service offered is divided into 3 successive steps:

- Feasibility study at the laboratory scale (transposition of the existing solution to the compound of interest: adjustment of the key operating parameters according to the characteristics of the compound to be formulated and the intended final application, production prototypes on a small-scale);

- Production of prototype on a pilot scale (i.e. 1-5 kilos);

- Transfer on a semi-industrial or industrial scale (i.e. 50 – 2000 kilos).

ANALYSIS AND CHARACTERIZATION PLATFORM

CAPSULAE offers its partner customers a high-performing and very complete set of analytical and characterization tools.

These services are both outside and within the framework of our contract research and prototype development services.

- Particle size analysis: powder, suspension, emulsion (micrometric to nanometric) by laser diffraction

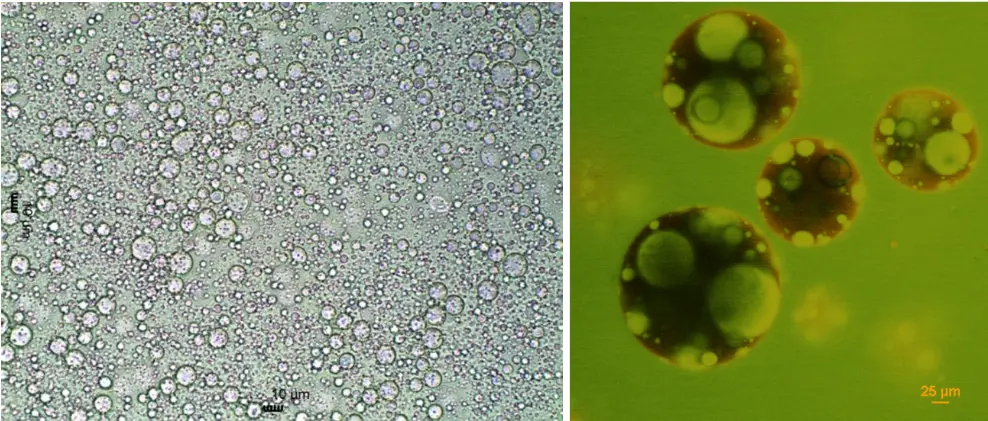

- Morphological analysis: optical, electron(ESEM), interferometric (surface state) microscopy

- Physical characterization of powders: Residual humidity, aw, bulk/packed density, absolute density, flowability

- Characterization of liquids: rheology, pH, conductimetry, osmolality, zeta potential

- Chemical/thermal characterization of powders: FTIR, DSC, DVS, melting point

- Stability tests, release kinetics: HPLC-DAD, UV-Visible spectrophotometer, oil oxidation test, kinetic tests in a simulated in-vitro environment, stability tests in oven with controlled humidity

For more information on our services, contact us at : customers@innov-ia.com

NEWS AND EVENTS CAPSULAE

Collaborative Research & Innovation: Le Mans Université, CNRS, and Capsulæ, with the support of the ANR, join forces to design biodegradable microcapsules

On Thursday, April 24, 2025, Le Mans Université, the CNRS, the La Rochelle-based company Capsulæ, the French National Research[...]

Emulsion-Based Microencapsulation Technologies

Microencapsulation is a key technology in the innovative ingredients industry. It involves encapsulating active substances within microparticles to enhance[...]

TECHNOLOGY FOCUS : DRIPPING

Encapsulation refers to all the technologies allowing to formulate one (or more) active ingredient(s) within individualized particles presenting a[...]