Facing climate challenges and increasing resource pressure, the food industry is at a turning point. Reducing waste, limiting raw material consumption, and extending ingredient shelf life are no longer just environmental goals—they are drivers of performance and competitiveness.

In this quest to balance industrial efficiency with environmental responsibility, innovation plays a central role. Designing more stable, better-protected, and more easily valorized ingredients is a concrete way to support sustainable food.

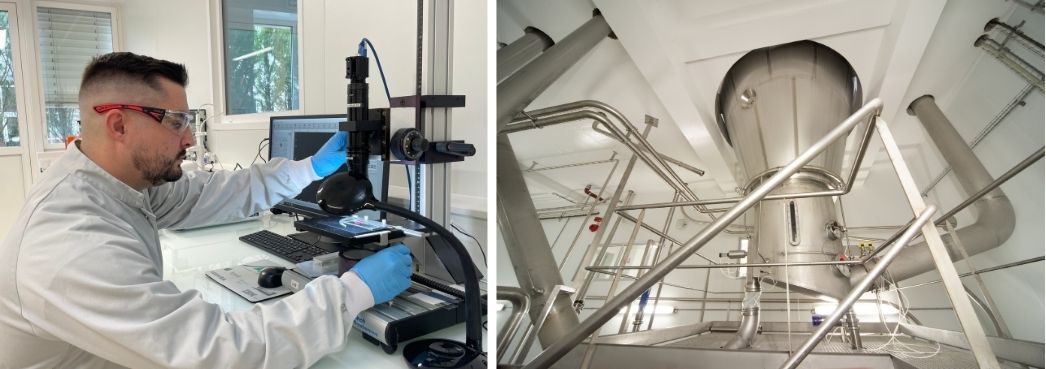

From this perspective, Innov’ia, an expert in custom formulation and production of functional ingredients, helps manufacturers implement leaner, more efficient, and resource-respecting solutions. With unique expertise in processing technologies and a strong CSR approach, the company contributes to rethinking ingredient design and usage to minimize waste across the value chain.

Sustainable Food Innovation: A Strategic Lever for Manufacturers

From Environmental Challenges to Profitability Imperatives

Nearly one-third of food produced globally is lost or wasted before reaching the consumer. In processing chains, these losses have a dual impact: environmental—through wasted resources, water, and energy—and economic, with rising costs linked to raw materials, storage, or non-compliance of finished products.

Manufacturers now face a complex equation: maintaining high performance while reducing their environmental footprint. CSR policies, societal expectations, and European regulations—such as the Green Deal and the “Farm to Fork” strategy—push the entire sector to rethink its practices.

In this context, sustainable food innovation is more than a trend: it is a strategic response to reconcile efficiency, compliance, and responsibility. Companies that develop more stable, durable, and resource-efficient products gain competitiveness while enhancing their brand image with customers and partners.

Towards More Responsible and Efficient Formulation

A key element of this transition lies in ingredient design and processing. Optimized formulation minimizes losses from the development stage: using the right dosage of actives, avoiding premature degradation, and improving preservation and stability.

Here, sustainability meets performance. By rethinking processes, integrating better-utilized raw materials, or applying circular approaches, manufacturers reduce both waste and dependence on costly resources. This approach extends from R&D to production: every stage becomes an opportunity to improve the product’s overall impact.

Sustainable food innovation is therefore not just about “doing more with less” but rethinking ingredient design itself: more stable, safer, easier to process—and ultimately, more respectful of planetary resources.

Reducing Waste: Acting at the Source Through Ingredient Mastery

Protecting Sensitive Actives to Prevent Performance Loss

A significant portion of industrial waste comes from premature ingredient degradation: oxidation, thermal instability, loss of efficacy or flavor. These alterations can compromise final product quality and lead to costly rejects.

Through processes such as microencapsulation or coating, it is now possible to preserve the performance of the most fragile actives. These technologies protect sensitive components (vitamins, flavors, probiotics, fatty acids, etc.) by isolating them in an appropriate matrix, controlling their release and extending their shelf life.

Direct benefits for manufacturers include:

- Improved ingredient stability throughout the manufacturing process;

- Reduced losses during handling, storage, or distribution;

- Lower dosage requirements for the same effectiveness.

By protecting the functional value of ingredients, technological innovation becomes a true lever for sustainable performance—reducing waste at the source while ensuring consistent results.

Optimizing Processing and Preservation

Reducing waste also means acting during processing: every stage counts, from drying to packaging. Ingredient stability depends as much on formulation as on handling and storage.

Innov’ia leverages unique expertise in functional powder design to optimize solubility, dispersibility, and moisture resistance. These properties enhance preservation and usability while reducing the risk of losses during transport or storage.

Key technologies such as spray drying and fluidized-bed granulation produce homogeneous, stable powders that are easy to integrate into final formulations.

Benefits for the production chain include:

- Fewer rejects due to texture or moisture non-conformities;

- Simplified logistics thanks to easier ingredient handling;

- Extended shelf life, leading to less long-term waste.

With this holistic approach, waste reduction becomes an integral part of ingredient design, supporting measurable and sustainable performance.

Extending Ingredient Life: Circular and Responsible Innovation

Rethinking the Lifecycle: From Formulation to Valorization

Extending ingredient life is not only about stability—it is about the overall lifecycle, covering design, processing, usage, and end-of-life.

By applying circular economy principles, Innov’ia helps clients reduce waste throughout the product journey, from R&D to co-product valorization.

This approach relies on a broad vision of sustainability:

- Designing more robust ingredients that maintain their properties under variable storage conditions;

- Reducing material losses throughout industrial processes;

- Giving a second life to by-products, transforming them into resources for new formulations.

By making circularity a strategic axis, Innov’ia addresses both environmental impact reduction and competitiveness enhancement. Through its Capsulae R&D center, the company promotes bio-based, biodegradable, or secondary-material solutions, fostering virtuous innovation.

Concrete Metrics to Measure Sustainability

Credible sustainability must be measurable. Innov’ia relies on tangible indicators and concrete investments to evaluate and reduce its impact.

Over €7 million have already been invested to improve environmental performance at its sites: air treatment, water and energy reduction, and valorization of industrial waste.

These commitments are supported by recognized certifications (FSSC 22000, FAMI-QS, Organic, Halal, Kosher on request), ensuring quality, safety, and traceability.

By combining technological expertise and environmental management, Innov’ia demonstrates that it is possible to extend ingredient life while reducing their planetary footprint—a coherent, measurable, and forward-looking approach.

Co-Developing Sustainable Solutions with Innov’ia

Sustainable innovation is built step by step with the right partners. At Innov’ia, every project is a custom collaboration, designed to combine technological performance with positive impact.

Through co-development, the company supports manufacturers from formulation to production, adapting each solution to technical, regulatory, and environmental requirements.

Concretely, this means:

- Integrated scientific and industrial expertise, from laboratory to production site;

- Proven processes (microencapsulation, coating, spray drying, etc.) to stabilize, protect, and valorize ingredients;

- Constant commitment to quality, traceability, and compliance.

Innov’ia does more than produce ingredients: it helps partners design more sustainable, competitive, and responsible products—a turnkey approach to turn today’s ideas into tomorrow’s solutions.

Conclusion – Together, Let’s Extend Ingredient Life for Sustainable Food

Sustainable food innovation is no longer optional: it is a transformation driver for the entire sector. Reducing waste, extending ingredient life, and minimizing environmental impact are levers for performance, compliance, and competitiveness.

With its expertise in custom formulation and production of functional ingredients, Innov’ia guides partners toward concrete, measurable, and responsible solutions. Its cutting-edge technologies, combined with a strong CSR approach, create safer, more stable, and resource-efficient ingredients.

👉 Want to develop more sustainable and high-performing ingredients?

Contact Innov’ia experts now to discuss your projects and turn your ideas into future-ready solutions.

FAQ – Innovating Sustainably in Ingredient Formulation

Table of contents

- Sustainable Food Innovation: A Strategic Lever for Manufacturers

- Reducing Waste: Acting at the Source Through Ingredient Mastery

- Extending Ingredient Life: Circular and Responsible Innovation

- Co-Developing Sustainable Solutions with Innov’ia

- Conclusion – Together, Let’s Extend Ingredient Life for Sustainable Food

- FAQ – Innovating Sustainably in Ingredient Formulation

Contact-us

"*" indicates required fields