Are you developing sensitive or high-value ingredients, but your production lines have reached their limits? Encapsulation is an essential technology to protect, stabilize, and enhance your formulations. Yet, setting up these processes in-house requires costly equipment, rare expertise, and thorough regulatory compliance. That’s where outsourcing becomes a strategic lever: increased flexibility, reduced risks, accelerated projects, and guaranteed quality. With more than 30 years of expertise and a state-of-the-art R&I center, Innov’ia offers its technologies and scientific know-how to transform your ideas into high-performance solutions, ready to be integrated into your finished products.

Why outsource your encapsulation processes?

Setting up an encapsulation line in-house can quickly turn into an obstacle course. Heavy investment in spray dryers or fluidized beds, recruiting hard-to-find experts, and meeting strict standards (ISO, FSSC, GMP, FAMI-QS…) all become hurdles that slow down your projects and increase your costs.

Outsourcing is quite the opposite. You gain flexibility, immediate access to specialized skills, and reduced risks. It also ensures that you can adjust your production volumes as needed—from prototype to industrial scale—without tying up your capital in complex infrastructures.

The strategic advantages of outsourcing

Reducing costs and gaining agility

Setting up an in-house encapsulation unit requires heavy investments: specialized equipment, ongoing maintenance, staff training… not to mention the time needed to reach optimal performance.

By outsourcing, you turn these fixed costs into controlled expenses. You immediately benefit from high-performing, flexible industrial tools, capable of producing both small test batches and industrial volumes. Result: you adapt your strategy to market needs without immobilizing your cash flow.

What concrete results can you achieve with microencapsulation?

Microencapsulation is not just a technology—it’s a real product performance lever. Discover 5 practical examples where it improves stability, solubility, or efficiency of sensitive ingredients.

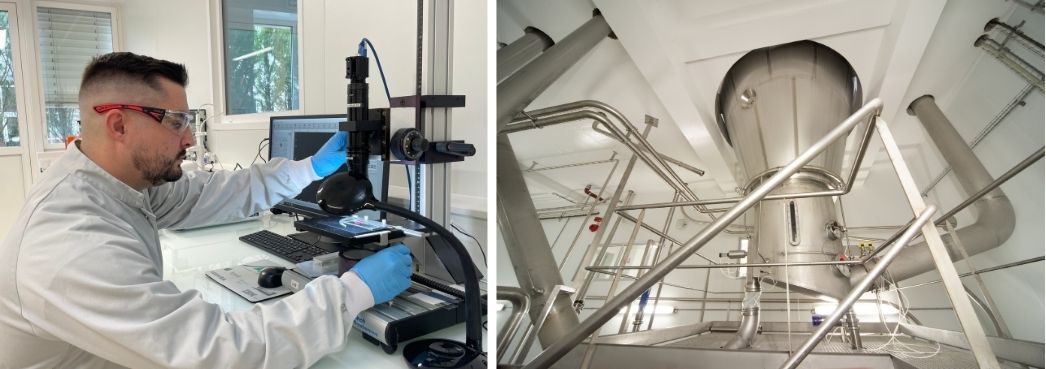

Accessing specialized and innovative expertise

Encapsulation is more than a technical process—it’s a scientific know-how built on years of experience. By collaborating with Innov’ia, you gain access to specialists in microencapsulation, coating, spray drying, or prilling, who can select the technology best suited to your constraints.

You also benefit from active R&D: more than 35 dedicated researchers and experts who can transform your ideas into concrete prototypes and support you all the way to industrial scale-up.

Securing quality and regulatory compliance

In sensitive sectors such as food, pharmaceuticals, or cosmetics, compliance is non-negotiable. Outsourcing to a certified partner ensures that you meet the strictest requirements: FSSC 22000, GMP, FAMI-QS, Kosher, Halal, Organic.

Outsourced encapsulation: what benefits for your products?

Outsourcing your encapsulation processes is not only about costs or internal organization. It’s also a direct way to enhance the performance and added value of your products.

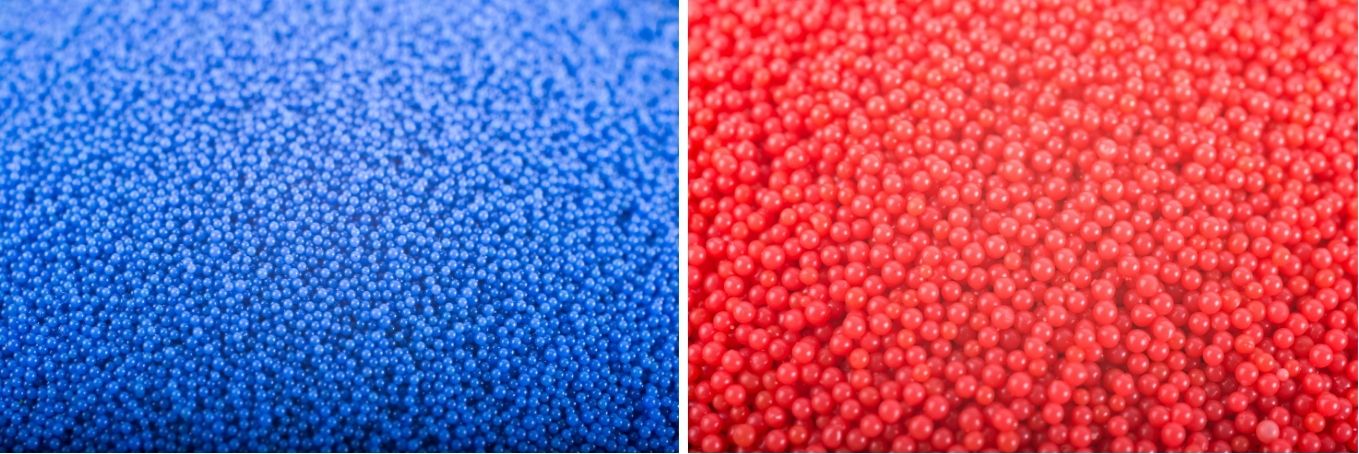

Protecting your sensitive actives

Fragile ingredients (vitamins, probiotics, flavors, cosmetic actives…) quickly lose their effectiveness when exposed to oxidation, moisture, or heat. With encapsulation, you:

- Increase the stability of your formulations,

- Extend product shelf life,

- Ensure consistent efficacy from manufacturing to the end user.

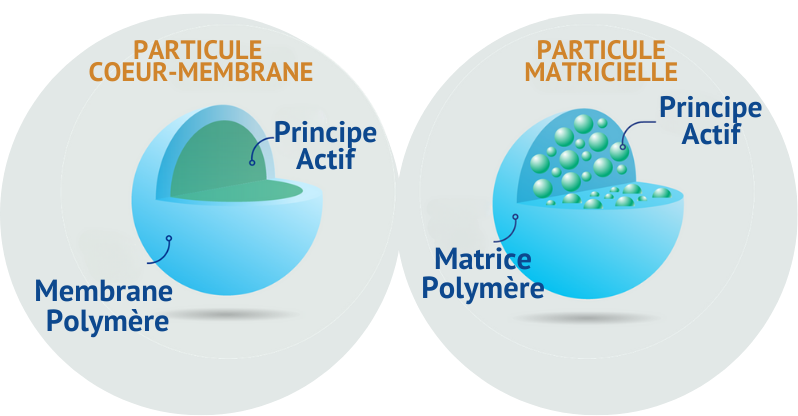

Controlling ingredient release

Depending on your needs, encapsulation can tailor the way the active is released in the body or final application:

- Progressive release for prolonged effect,

- Targeted release for enhanced efficacy,

- Delayed release to protect actives until the right moment.

These options are especially strategic in nutrition, animal health, or pharmaceuticals, where precision of action is as important as effectiveness.

Optimizing the user experience

A high-performing product must also be pleasant to use. Encapsulation improves powder solubility and handling, while enhancing sensory aspects (taste, odor, texture). Result: products that are not only more reliable but also more appealing to your end customers.

How do Innov’ia’s services and expertise ensure the stability and durability of your ingredients?

Stability is key to ensuring the performance and longevity of your products. Here we explain how Innov’ia’s solutions protect your sensitive actives and increase their market value.

Innov’ia: a trusted partner for your encapsulation projects

A comprehensive offer from R&D to industrial production

With Innov’ia, you don’t need multiple service providers. The company supports you at every stage: formulation, co-development, proof of concept, scale-up, and contract manufacturing. This integrated approach allows you to move quickly from idea to market while securing each project phase.

High-performance industrial infrastructures

Relying on 4 modern production sites, Innov’ia offers unique capabilities in Europe:

- 13 fluidized bed units,

- 8 spray dryers,

- 2 prilling units.

This industrial capacity ensures flexible, responsive production adapted to both small batches and industrial volumes.

Recognized international expertise

With more than 35 R&I experts and over 300 employees in France, Innov’ia combines scientific know-how with industrial strength. Its experience spans diverse markets—food, human nutrition (including infant nutrition), animal nutrition and health, cosmetics, pharmaceuticals, biocontrol—allowing it to adapt its solutions to the regulatory and commercial requirements of each sector.

By choosing Innov’ia, you select a reliable and innovative technology partner, capable of transforming your drying and encapsulation projects into true competitive advantages.

Outsourcing your encapsulation processes: a strategic choice for the future

Encapsulation is more than just a transformation technology—it’s a strategic lever to protect your actives, improve your products, and accelerate your development. In-house, obstacles abound: high costs, regulatory complexity, lack of agility. In contrast, outsourcing gives you flexibility, secures your processes, and provides access to top expertise without tying up your resources.

With its industrial infrastructures, cutting-edge R&I center, and more than 30 years of experience, Innov’ia is the ideal partner to turn your encapsulation projects into tangible successes.

👉 Want to explore the benefits of outsourcing for your business? Contact Innov’ia’s experts today and give your formulations the performance they deserve.

FAQ – Outsourcing encapsulation with Innov’ia

Table of contents

- Why outsource your encapsulation processes?

- The strategic advantages of outsourcing

- Outsourced encapsulation: what benefits for your products?

- Innov’ia: a trusted partner for your encapsulation projects

- Outsourcing your encapsulation processes: a strategic choice for the future

- FAQ – Outsourcing encapsulation with Innov’ia

Contact-us

"*" indicates required fields