A cosmetic product only has value if it remains effective until the very last day of use. However, heat, light, or oxidation can destabilize active ingredients and reduce their effects. The result: loss of efficacy, potential safety and health risks for the consumer, and a direct impact on the brand’s reputation.

Ensuring the stability of cosmetic actives means guaranteeing high-performing products that comply with European standards and deliver on their promises to consumers. With over 30 years of expertise, Innov’ia supports brands in transforming sensitive actives into reliable, long-lasting solutions.

Let’s explore why stability is a strategic challenge and how it can become a key differentiator in the cosmetics market.

Why Is the Stability of Cosmetic Active Ingredients Crucial?

A Product Performance Issue

In a market where consumers expect visible and long-lasting results, active ingredient stability is a decisive factor. An unstable active may lose its effectiveness even before the product’s end of use. The consequence: the promise of hydration, radiance, or anti-aging effects is not kept, undermining consumer trust and the brand’s reputation. Ensuring stability therefore means guaranteeing products that deliver results from the first to the last use.

A Regulatory Imperative

Beyond customer satisfaction, stability is a regulatory requirement. European Regulation 1223/2009 and ISO 22716 standards mandate stability testing before market release. These tests assess the product on several levels:

- Physical stability (color, viscosity, texture)

- Chemical stability (pH, oxidation, active ingredient degradation)

- Microbiological stability (absence of bacteria, yeasts, molds)

- Packaging compatibility

An unstable product may be rejected, require costly reformulation, or face commercialization delays. For manufacturers, this means financial losses and strategic setbacks against competitors. This is why many players in the industry rely on partners capable of developing compliant, safe, and high-performing cosmetic products from the design stage.

The Challenges of Active Ingredient Stability in Cosmetics

Common Degradation Factors

Cosmetic actives are particularly sensitive to their environment. Several factors can compromise their effectiveness:

- Oxidation, triggered by exposure to air or UV rays

- Temperature and light, which accelerate molecular breakdown

- Inappropriate pH, which can alter the chemical structure of actives

- Interactions with other formula ingredients or packaging materials

These constraints are even more critical in cosmeceuticals, where actives are used at high concentrations to deliver visible effects. Their stability then becomes a true technical challenge.

👉 CTA: To dive deeper into the mechanisms of active degradation, consult La Fabrique 621’s article on cosmetic stability, which details the main parameters to monitor.

Consequences of Poorly Controlled Instability

An unstable active quickly leads to major issues for the brand:

- Loss of efficacy → the product fails to meet marketing promises (anti-aging, hydration, radiance).

- Health risks → possible appearance of microorganisms or unwanted by-products.

- Industrial costs → reformulation, raw material waste, product launch delays.

In short, poorly controlled instability can compromise customer satisfaction, user safety, and project profitability.

How to Ensure the Stability of Cosmetic Active Ingredients?

Scientifically Validated Stabilization Methods

To guarantee product performance, several scientifically recognized stabilization approaches are used:

- Steric and electrostatic stabilization: prevent particle aggregation and ensure homogeneous distribution of actives.

- Use of surfactants and HLB balance: promote proper dispersion of actives and maintain formula texture.

- Controlled formulation conditions: adjustment of pH, use of appropriate antioxidants or preservatives to limit degradation.

These methods not only preserve the properties of actives but also ensure an optimal user experience, with a stable and pleasant texture from start to finish.

Innov’ia’s Technological Solutions for Stability

Innov’ia leverages its technological expertise to turn stability into a real competitive advantage. Among its key processes:

- Microencapsulation: protects sensitive actives from oxidation, heat, or unwanted interactions, while enabling targeted release.

- Spray drying and granulation: improve storage and handling of powders, while enhancing solubility.

- Coating and prilling: optimize stability and ease of use, with the possibility to control active release rates.

These solutions are never presented as isolated technical feats, but as concrete tools to help brands develop reliable, compliant, and high-performing cosmetics.

How to Ensure the Stability of Cosmetic Active Ingredients?

Scientifically Validated Stabilization Methods

To guarantee product performance, several scientifically recognized stabilization approaches are used:

- Steric and electrostatic stabilization: prevent particle aggregation and ensure homogeneous distribution of actives.

- Use of surfactants and HLB balance: promote proper dispersion of actives and maintain formula texture.

- Controlled formulation conditions: adjustment of pH, use of appropriate antioxidants or preservatives to limit degradation.

These methods not only preserve the properties of actives but also ensure an optimal user experience, with a stable and pleasant texture from start to finish.

Innov’ia’s Technological Solutions for Stability

Innov’ia leverages its technological expertise to turn stability into a real competitive advantage. Among its key processes:

- Microencapsulation: protects sensitive actives from oxidation, heat, or unwanted interactions, while enabling targeted release.

- Spray drying and granulation: improve storage and handling of powders, while enhancing solubility.

- Coating and prilling: optimize stability and ease of use, with the possibility to control active release rates.

These solutions are never presented as isolated technical feats, but as concrete tools to help brands develop reliable, compliant, and high-performing cosmetics.

Innov’ia: An Expert Partner to Secure Your Cosmetic Projects

Recognized Scientific and Industrial Expertise

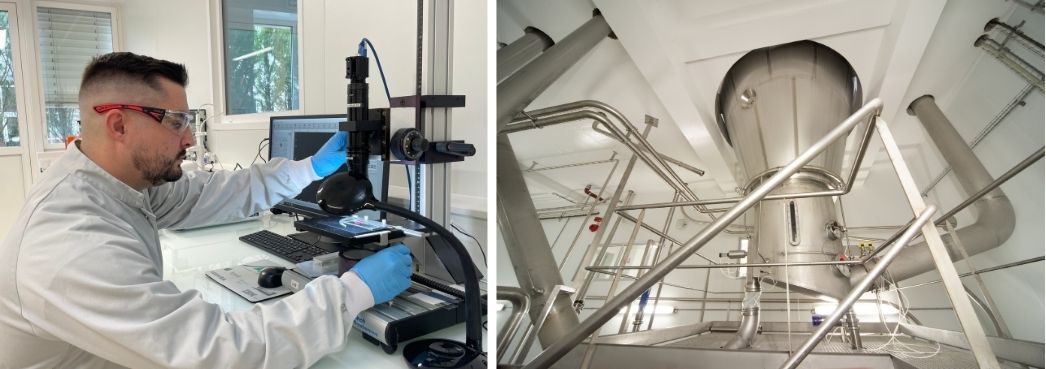

For over 30 years, Innov’ia has supported cosmetic manufacturers in the design and production of functional ingredients. Its R&I center in La Rochelle brings together more than 35 experts specializing in the stabilization and encapsulation of sensitive actives. With this dual scientific and industrial expertise, Innov’ia guides its partners from lab-scale formulation to large-scale production with proven, reliable solutions.

A Tailored, Integrated Offer

Innov’ia’s approach is based on co-development, building solutions that are fully adapted to each client’s specific needs. The company provides:

- Custom formulation of functional ingredients

- Co-development of prototypes and proof of concept

- Industrial-scale contract manufacturing

- Integrated analytical and quality services

Innov’ia guarantees the highest standards of safety, traceability, and regulatory compliance: FSSC 22000, GMP, and Halal, Kosher, Organic certifications upon request. Its commitment to sustainability further enhances the value of its solutions.

Client Benefits: Why Work with Innov’ia?

Partnering with Innov’ia means more than accessing advanced technology: it means benefiting from complete support that secures and accelerates cosmetic projects.

- Secure product development: mastering stability reduces regulatory test failures and minimizes costly reformulations.

- Faster time-to-market: proven processes and integrated organization save valuable time for new launches.

- Guaranteed performance and compliance: every ingredient is designed to meet scientific and regulatory standards, while delivering on consumer expectations.

- Enhanced brand image: a stable, effective, and safe product inspires trust, builds loyalty, and creates lasting competitive advantage.

With Innov’ia, active stability is no longer just a technical challenge but a real lever for differentiation and growth in cosmetic and skincare markets.

Conclusion – Make Cosmetic Active Stability Your Competitive Advantage

In cosmetic projects, active stability is not optional: it ensures that products remain effective, safe, and compliant until the very last day of use. Without it, you risk losing time, money—and consumer trust.

With Innov’ia, you have a partner capable of transforming sensitive actives into reliable, high-performance ingredients. Our team supports you from lab to industrial production to secure launches and accelerate time-to-market.

👉 Do you want to develop cosmetics that deliver on their promises and stand out sustainably? Tell us about your project today.

FAQ – Cosmetic Active Stability and Innov’ia Expertise

Table of contents

- Why Is the Stability of Cosmetic Active Ingredients Crucial?

- The Challenges of Active Ingredient Stability in Cosmetics

- How to Ensure the Stability of Cosmetic Active Ingredients?

- How to Ensure the Stability of Cosmetic Active Ingredients?

- Innov’ia: An Expert Partner to Secure Your Cosmetic Projects

- Client Benefits: Why Work with Innov’ia?

- Conclusion – Make Cosmetic Active Stability Your Competitive Advantage

- FAQ – Cosmetic Active Stability and Innov’ia Expertise

Contact-us

"*" indicates required fields